torsion test on mild steel conclusion|modulus of rigidity mild steel : discount store In this experiment, solid cylindrical specimen of steel or brass will be subjected to a torsional load. The test will be conducted until failure (i. it will end in the fracture). During the test, the angle of . Resultado da 18 de out. de 2023 · A palavra ninfeta é um termo que tem sido amplamente utilizado na literatura e na cultura popular, muitas vezes com uma .

{plog:ftitle_list}

1 Litros = 1000 Mililitros: 10 Litros = 10000 Mililitros: 2500 Litr.

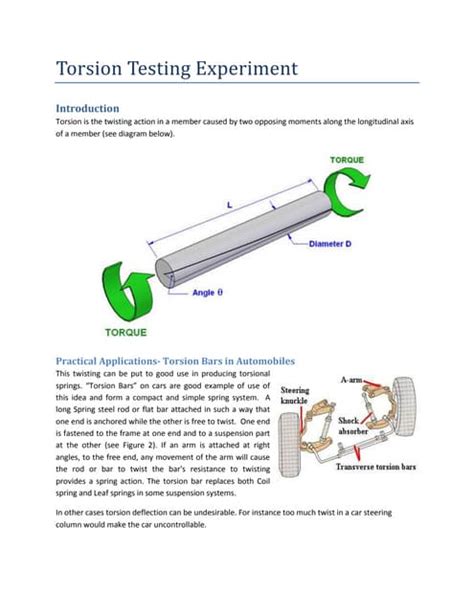

Purpose: To study the shear stress ~ shear strain behavior of the material. To study the failure pattern of these materials in torsion. To determine the mechanical properties, .

types of impact testing

Using the torsion testing machine, we will find out modulus of rigidity and shearing property of mild steel specimen. Main objective of torsion testing experiment is following, To find modulus of rigidity of test machine. To draw .In this experiment, solid cylindrical specimen of steel or brass will be subjected to a torsional load. The test will be conducted until failure (i. it will end in the fracture). During the test, the angle of .Torsion testing is used to examine how a material or test sample behaves when twisted or subjected to torsional stresses as a consequence of applied moments that create shear stress .

Torsion testing predicts a material’s behavior under twisting forces by assessing key properties such as torsional strength, shear modulus, yield strength in torsion, ductility, and brittleness. It enables the understanding of fatigue behavior, . The conclusion of a torsion test experiment is that the material's torsional strength and stiffness can be determined by measuring the torque and angle of twist. This information can then be used to compare the .This lab report summarizes an experiment to determine the shear modulus of mild steel samples under torsion. Cylindrical mild steel specimens were subjected to increasing torque loads, and the angle of twist was measured.

Spheroidizing annealing and torsion testing of 0.027 wt% carbon steel rod were conducted to evaluate spheroidization kinetic behavior at 943 K (670 °C) under deformed and non-deformed states.

Solid ductile metal bars (mild steel): Ductile torsion failure reveals a flat, transverse break having smooth shear surface and microvoid formation. The failure occurs along a plane perpendicular to the axis, in this plane the .

This torsion test experiment is carried out on rods made of mild steel which is a standard torsion application instrument with in diameter 0 and 0 in length. The rod is connected to a machine that measures torque at one end, and the other .

EQUIPMENT & MATERIALS 3.1 Equipment Torsion Tester Machine 3.2 Materials Aluminum & Mild Steel ENT 251/4 – Solid Mechanics Laboratory Module 15 Fig. 1 Torsion test machine 3. TORSION TEST The .Torsion testing involves the twisting of a sample along an axis and is a useful test for acquiring information like torsional shear stress, maximum torque, shear modulus, and breaking angle of a material or the interface between two materials. . a mild steel and an AA 6061-T6 alloy. Figure 2.2. . 5 Conclusions.Experiment Two- Torsional test Experiment Two (2) Torsional testing of Circular Shafts Introduction: Torsion occurs when any shaft is subjected to a torque. This is true whether the shaft is rotating (such as drive shafts on engines, motors and turbines) or stationary (such as with a bolt or screw).

This lab report summarizes an experiment to determine the shear modulus of mild steel samples under torsion. Cylindrical mild steel specimens were subjected to increasing torque loads, and the angle of twist was measured. By plotting torque versus angle of twist, the shear modulus could be calculated from the slope. The experiment aimed to find properties like shear stress, shear . The video describes how to experimentally find the modulus of rigidity of a mild steel.This is an important test in automobile manufacturing. The video was .

experiment torsion test objective to determine the modulus of rigidity, maximum shearing stress, maximum shearing strain and ratio for the tested specimen. ii. Skip to document. . the fracture will occur between 100 to 200 rotations and 200 to 300 rotations for the mild steel and brass material respectively and continued to specimen fracture .No: 4 Date: AIM To conduct torsion test on mild steel rod and to find its modulus of rigidity. APPARATUS REQUIRED i) Torsion testing machine ii) Mild steel rod THEORY Torsion is quite instrumental in determining the valve of modulus of rigidity (ratio of shear stress to shear strain) of a metallic specimen. A torsion test twists the mild steel rod by attaching one end to the machine and applying a moment to the other end, causing the sample to spin around its axis. . Conclusion. The article accesses the material torsion and provides a detailed graphical explanation with all the possible comparisons which can be referred for further Research . 1.1 Aim of torsion test lab report Torsional Testing of Brass, Steel and Aluminum 1.2 Objective . Learn the basics of torsion test theory; . 8.0 Conclusion Torsion test have been perform on three different materials (brass, steel and aluminum) and with the help of experimental data, value of modulus of rigidity and shear stresses is .

This paper examines the results obtained from combined tension–torsion loading tests carried out on Mild steel (En8) specimen. The loading of the specimen was carried out in different modes: (i) maintaining tensile force or axial displacement constant and increasing torque or angle of twist; (ii) maintaining torque or angle of twist constant and increasing load or axial .

Torsion Test on Mild Steel. To study the mechanical properties of mild steel under torsion. Community Links Sakshat Portal Outreach Portal FAQ: Virtual Labs. Contact Us Phone: General Information: 011-26582050 Email: [email protected] . Follow Us.

torsion test experiment 2 pdf

To conduct torsion test on mild steel. Apparatus:- 1. A torsion test machine along with angle of twist measuring attachment. 2. Standard specimen of mild steel. 3. Steel rule. 4. Vernnier caliper or a micrometer. Theory:- For transmitting power through a rotating shaft it is necessary to apply a turning force. .5. Torsion Test for Mild Steel Bars - Free download as Word Doc (.doc / .docx), PDF File (.pdf), Text File (.txt) or read online for free. The document summarizes a laboratory experiment to test the torsion properties of mild steel bars. The .A torsion test is a mechanical testing method that evaluates the properties of materials or devices under stress caused by angular displacement. During a torsion test, a specimen is subjected to a twisting or torsional force, which .

Lab report engr 2332 mechanics of materials lab no. torsion test and analysis austin ciervo march 29, 2018 objectives the purpose of this experiment is to . A steel rod is then inserted through the two holes. represents the distance from .In the present paper, the effect of different specimen dimensions on the modulus of rigidity of mild steel (AISI 1020) in torsion testing is investigated. The experiments were conducted with dimension variables such as total length, useful length, outer diameter and fillet radius at different levels. For every combination of dimension variables .IS 1717 (2012): Metallic Materials - Wire - Simple Torsion Test,Third Revision, 2012. F.L. Singer. Strength of Materials, Harper and Row Publishers.Discussion Based on the experiment, the specimen’s material used was mild steel. The dimensions for the specimen was 0.08 m for its length, 0.006 m for the diameter and 0.003 m for the radius. The value of polar moment of inertia, J for this experiment is 1.272 x 10-10 m 4 . In the first 4 readings, the increment of each angles was 90 o each. The scale readings start from .

Torsion Test on Mild Steel. To study the mechanical properties of mild steel under torsion. Community Links Sakshat Portal Outreach Portal FAQ: Virtual Labs. Contact Us Phone: General Information: 011-26582050 Email: [email protected] . Follow Us.

This paper examines the results obtained from combined tension–torsion loading tests carried out on Mild steel (En8) specimen. The loading of the specimen was carried out in different modes: (i) maintaining tensile force or axial displacement constant and increasing torque or angle of twist; (ii) maintaining torque or angle of twist constant and increasing load or axial . Understanding Torsion TestingIn the field of mechanics and materials science, torsion testing is a crucial method for assessing the strength and behavior of materials under twisting forces. This comprehensive guide will provide an in-depth understanding of torsional testing, the machines used, and their applications in evaluating the performance and reliability .

Preparation of Specimen: Initially, the steel rod specimen is cleaned and gauge length is marked on it. The gauge length is calculated by the formula .. The gauge length can be marked on the specimen by punching tool. Range Calculation: A tensile stress value is assumed for which the maximum expected load capacity of the rod is calculated. From this, the range is calculated .Torsion Test on Mild Steel | KTU S4 Material Testing Lab | Experiment Setup

Double shear test is used to determine the shear strength (ultimate shear stress) of the mild steel specimen. Universal testing machine (UTM) is used for performing double shear test. There are two types of UTM namely: screw type and .To study the mechanical properties of mild steel under torsion. STEPS: Click on the Torsion test on Vertical Mild Steel file, a window will open as shown. Click on the NEXT button to move to the next step. Click on vernier calliper to measure the diameter of the specimen. Click on measuring scale to measure the Length of the specimen between .

studocu torsion test

web25 de out. de 2023 · Welcome to the fascinating realm of Lala.Bet Casino is a platform where thrill, adventure, and potentially hefty rewards are just a click away—launched in 2022 and holding a license from the esteemed .

torsion test on mild steel conclusion|modulus of rigidity mild steel